The integrity and efficiency of PCB connections define modern electronics. Innovations in PCB connectors have produced reasonably priced, user-friendly, high-performance solutions. Two especially noteworthy components that simplify fabrication and assembly are the 1.85 vertical launch PCB connection and solderless PCB connector. These connections are used in the telecoms and automotive sectors to move power and signals between devices.

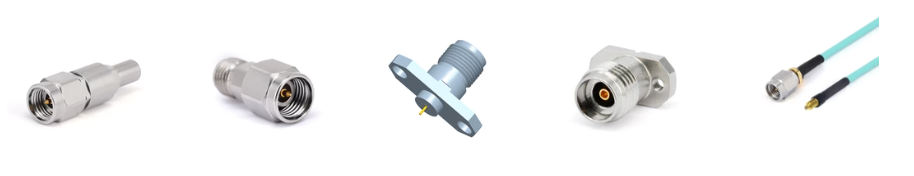

A soldersless PCB connector

Solderless PCB connectors enable two electronic components on a PCB without soldering. This special design speeds up manufacture, improves assembly precision, and helps to avoid overheating damage. Applications calling for dependability, speed, and flexibility will find the solderless PCB connector perfect.

One of main advantages of these connectors is reusability. Replacing and changing soldered connectors is more difficult than solderingless connectors. Frequency of device design changes and prototype development depend on this.

Presenting the 1.85 Vertical Launch PCB Connector

Regarding advanced connectors, the 1.85 vertical launch PCB connector is very remarkable. With this connector, signal transmission is outstanding and fit for high-frequency uses. RF applications take advantage of the 1.85 vertical launch PCB connector, which is small and simple to integrate.

The vertical launch design of the connector lets PCBs be mounted perpendicular-wise. This design helps the connector to have better electrical performance, hence lowering interference. The 1.85 vertical launch PCB connector fits for wireless communications or high-speed signal processing.

The main advantages of Solderless PCB Connectors

● On hand soldering: solderless design reduces time and effort; hence, assembly is faster and more efficient.

● High dependability: The connection process leaves component damage free from extreme temperature exposure by not involving heat.

● Because they are reusable: solderless connectors are great for prototyping and testing.

● Working with many PCB designs: these connections can manage several voltages and signal kinds.

Why in PCB design would one use solderless connectors?

Your next design could increase manufacturing speed and quality by using a solderless PCB connector. Eliminating soldering helps to simplify assembly and lower failure points. These connectors might be put in place without instruction, therefore optimizing your manufacturing line and saving money and time.

A solderless PCB connector becomes useful when replacements or repairs are required. These connectors' simplicity of use gives design iterations and testing freedom.

Conclusion

Applications requiring little interference and exact signal integrity for high frequencies would find the 1.85 vertical launch PCB connector perfect. For modern RF and communication systems, its small scale and vertical orientation make perfect fit. In telecommunication, wireless, and high-performance electronics, the 1.85 vertical launch PCB connector guarantees consistent and high-quality performance.

As demand for faster and more effective electronics grows, solderless PCB connectors and 1.85 vertical launch PCB connectors can enhance PCB functionality and efficiency.

Write a comment ...